Skip to the good bit

ToggleThe tire manufacturing industry, critical to the global automotive sector, has undergone significant transformations due to advancements in industrial automation. From the early days of manual labor-intensive processes to the current use of sophisticated machinery, the evolution of tire production highlights the impact of technological progress. A pivotal component in this modern automation landscape is the servo drive controller, which enhances the precision and efficiency of tire manufacturing equipment. This article explores the integration of industrial automation in tire manufacturing, providing a historical perspective and examining the current state of the art.

Historical Context and Evolution

The tire manufacturing process has not always been as streamlined as it is today. Historically, the production of tires was a predominantly manual process. In the early 20th century, the building of tires required significant human labor, from mixing rubber compounds to molding and curing. A notable example from history is the Ford Motor Company’s adoption of the assembly line in the 1910s, which, while not fully automated, significantly increased the efficiency of automobile manufacturing, including tires. This marked the beginning of mechanization in industries where manual processes had been the norm.

However, true automation began to take hold in the mid-20th century with the introduction of specialized machines for tasks such as extrusion and curing. The development and implementation of these machines paved the way for the modern, highly automated tire production lines seen today.

Introduction to Industrial Automation in Tire Manufacturing

Today, industrial automation in tire manufacturing encompasses a wide range of processes, each optimized for efficiency, safety, and product quality. Key stages in the automated tire manufacturing process include:

- Material Preparation: Raw materials such as natural and synthetic rubber, carbon black, and various chemicals are precisely mixed using automated systems. Servo drive controllers play a crucial role here by ensuring the exact movements and speeds of mixers, guaranteeing a consistent compound quality.

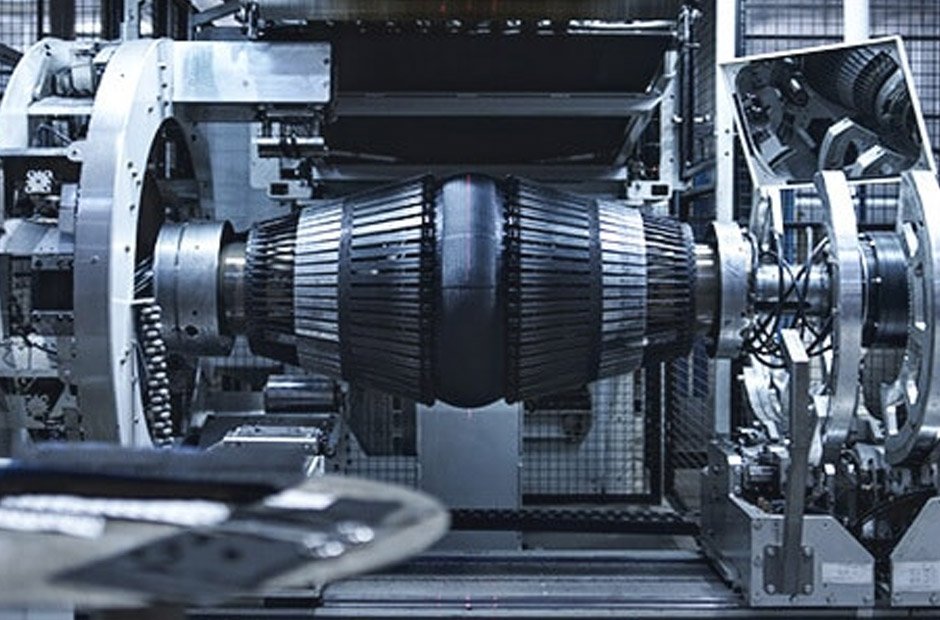

- Component Assembly: Tires are composed of different components like treads, sidewalls, beads, and liners. Automated machinery, controlled by servo drives, assembles these components with high precision. The servo systems allow for the accurate layering and positioning necessary to meet stringent quality standards.

- Tire Building: One of the most critical steps in tire manufacturing is the building stage, where all components are assembled into a ‘green tire.’ This is done on tire building machines, which are often equipped with servo drive controllers to manage the complex movements required during assembly, ensuring each tire is constructed correctly.

- Curing and Vulcanization: After assembly, tires undergo curing and vulcanization to set the shape and develop the physical properties. Automation in this stage includes presses and heating systems that are meticulously controlled to apply the right amount of heat and pressure for the specified time.

- Inspection and Testing: Finally, each tire is inspected and tested to ensure it meets safety and performance standards. Automation technologies, including machine vision and pressure testing equipment, are used to detect defects and non-conformities.

Benefits of Automation in Tire Manufacturing

Enhanced Productivity: Automation allows tire manufacturers to produce tires faster while reducing human error and fatigue. This results in higher productivity levels and the ability to meet increasing market demands efficiently.

Improved Quality and Consistency: The precision afforded by servo drive controllers in automated equipment ensures that every tire meets the same high standards of quality and performance. Consistency is crucial in the tire industry, where safety and reliability are paramount.

Cost Reduction: While the initial investment in automated machinery can be high, the long-term savings on labor costs and the reduction in waste lead to significant cost reductions.

Worker Safety: Automating dangerous or physically demanding tasks reduces the risk of accidents and injuries on the factory floor, promoting a safer work environment.

Challenges and Future Trends

Despite the benefits, integrating automation in tire manufacturing is not without challenges. The cost of implementing advanced technologies can be prohibitive for smaller manufacturers. Additionally, there is a continuous need for skilled technicians to operate and maintain these sophisticated systems.

Looking ahead, the future of automation in tire manufacturing is likely to be influenced by advancements in AI and machine learning, enabling even greater efficiencies and predictive maintenance capabilities. As environmental concerns continue to grow, there is also a push towards more sustainable manufacturing practices, with automation playing a key role in reducing waste and energy consumption.

Conclusion

The integration of industrial automation, particularly technologies like servo drive controllers like the DKC01.3-200-7-FW, has fundamentally changed the landscape of tire manufacturing. From historical manual processes to modern automated production lines, the evolution of this industry highlights the relentless pursuit of efficiency and quality. As manufacturers continue to embrace new technologies, the tire industry is set to experience further innovations that will enhance its global competitiveness and sustainability.